UL 94设备和器具部件材料的可燃性能试验返回 Back

| Test item 测试名称: | |

| Test For Flammability of Plastic Materials for Parts in Devices and Appliances | |

| 设备和器具部件材料的可燃性能试验 | |

|

|

|

| Test info 测试内容: | |

| Test Items | Relevant Standards |

| 水平燃烧(自撑料) | UL 94:1997, ASTM D635 |

| UL94 HB | IEC 60695-11-10 |

| conditioning | 23 ±2°C and 50±5 percent relative humidity for a minimum of 48 hours |

| 垂直燃烧(自撑料) | ASTM D3801-00/IEC 60695-11-10 |

| UL94 V0,V1,V2 | |

| conditioning | 23 ±2°C and 50±5 percent relative humidity for a minimum of 48 hours and preconditioned in an air-circulating oven for 168 hours at 70±1°C and then cooled in the desiccator for at least 4 hours at room temperature, prior to testing. |

| 垂直燃烧(自撑料) | ISO 1035 |

| UL94 5VA, 5VB | ASTM D5048 |

| conditioning | 23 ±2°C and 50±5 percent relative humidity for a minimum of 48 hours and preconditioned in an air-circulating oven for 168 hours at 70±1°C and then cooled in the desiccator for at least 4 hours at room temperature, prior to testing. |

| 水平燃烧(泡沫材料) | ASTM D4986/ISO 3852 |

| UL94 HBF, HF-1, HF-2 | IEC 60695-11-10 |

| conditioning | 23 ±2°C and 50±5 percent relative humidity for a minimum of 48 hours and preconditioned in an air-circulating oven for 168 hours at 70±1°C and then cooled in the desiccator for at least 4 hours at room temperature, prior to testing. |

| 垂直燃烧(软质塑料) | ISO 9773 |

| UL94 VTM0, VTM-1, VTM-2 | ASTM D4804 |

| conditioning | 23 ±2°C and 50±5 percent relative humidity for a minimum of 48 hours and preconditioned in an air-circulating oven for 168 hours at 70±1°C and then cooled in the desiccator for at least 4 hours at room temperature, prior to testing. |

| Sample Required and Turnaround Time, 所需样品及时间 | ||

| Test Items | TAT (Working Days) | |

| HB | 7 | |

| 12 pieces with the size of 125 ±5 mm long by 13.0 ±0.5 mm wide, and provided in the minimum thickness and 3.0 (-0.0 +0.2) mm thick. The 3.0 mm thick specimens are not necessary if the minimum thickness is greater than 3.0 mm, or the maximum thickness is less than 3.0 mm. The maximum thickness is not to exceed 13 mm. The maximum width is not to exceed 13.5 mm, the edges are to be smooth, and the radius on the corners is not to exceed 1.3 mm. | ||

| 12 pieces with the size of (125 ± 5) × (13 ± 0,2) mm X thickness(需要提供测试的最小厚度样品和3毫米厚度样品,若样品最小厚度大于3mm,或者最大厚度小于3MM,则可以不用提供3mm样品;样品最大厚度不超过13mm,最大宽度不超过13.5mm,) | ||

| V0, V1, V2 | 14 | |

| 17 pieces with the size of 125 ±5 mm long by 13.0 ±0.5 mm wide, and provided in the minimum and maximum thicknesses. The maximum thickness is not to exceed 13 mm. Specimens in intermediate thicknesses are also to be provided and shall be tested if the results obtained on the minimum or maximum thickness indicate inconsistent test results. Intermediate thicknesses are not to exceed increments of 3.2 mm. Also, the edges are to be smooth, and the radius on the corners is not to exceed 1.3 mm. | ||

| 17 pieces with the size of (125 ± 5) × (13 ± 0,2) mmX thickness(需要提供测试的最小厚度样品和最大样品厚度;样品最大厚度不超过13mm,如果最小厚度样品和最大厚度样品得出的结果不一致,则还需要提供中间尺寸样品,中间尺寸厚度跨度不超3.2mm) | ||

| 5VA, 5VB | 14 | |

| 32 pieces with (125 ± 5) × (13± 0.5) mm X minimum thickness AND 10 pieces 150 ± 5 × 150± 5 mm X minimum thickness | ||

| 32 pieces with (125 ± 5) × (13± 0.5) mm X 最小厚度 和 10 pieces 150 ± 5 × 150± 5 mm X最小厚度 (最大厚度不超过 13mm) | ||

| HBF, HF-1, HF-2 | 14 | |

| 17 pieces 150 ±5 mm long by 50 ±1 mm wide, in the minimum and maximum thicknesses covering the thickness range to be considered. Specimens tested by this method are limited to a maximum thickness of 13 mm. Specimens in intermediate thicknesses are also to be provided and shall be tested if the results obtained on the minimum and/or maximum thickness indicate inconsistent test results. Intermediate thicknesses are not to exceed increments of 6 mm. The maximum width is not to exceed 50 mm. The edges are to be smooth and the radius on the corners is not to exceed 2 mm | ||

| 17 pieces (150± 5) X (50± 1) mm X thickness (最小厚度和最大厚度都要提供, 当最大厚度和最小厚度的测试结果不一致,则中间的厚度也要提供,间隔不要超过6mm,试样宽度不要超过50mm) | ||

| VTM0, VTM-1, VTM-2 | 14 | |

| 17 pieces, 200 ±5 mm in length by 50 ±1 mm in width, in the minimum and maximum thicknesses that are to be tested covering the thickness range under consideration. Specimens in intermediate thicknesses are also to be provided and shall be tested. if the results obtained on the minimum and/or maximum thicknesses indicated inconsistent test results | ||

| 17 pieces (200± 5) X (50± 1)mm X thickness (最小厚度和最大厚度都要提供,这样可以认为测试结果对整个厚度系列有效,但当最小厚度和最大厚度的测试结果不一致时,中间的厚度也要提供) | ||

Others 其他信息:

1. UL94垂直燃烧,要求前处理70度168小时, 所以不能申请加急服务

2. 在安全测试实践中,我们对材料安全性评估其中一个重要的参数就是材料的阻燃等级。而UL94标准其适用于设备和电器的塑料零件的可燃性试验,它提出的燃烧等级划分是应用最广泛的塑料材料可燃性能标准。它用来评价材料在被点燃后熄灭的能力。根据燃烧速度、燃烧时间、抗滴能力以及滴珠是否燃烧可有多种评判方法。

UL94燃烧测试按阻燃要求和等级的不同分为:HB,V-0,V-1,V-2,5VA,5VB,VTM-0,VTM-1,VTM-2,HBF,HF1,HF2等12个阻燃等级。

其中我们以塑料材料为例,其的阻燃等级由HB,V-2,V-1向V-0逐级递增。

HB:UL94标准中最低的阻燃等级。要求对于3到13 毫米厚的样品,燃烧速度小于40毫米每分钟;小于3毫米厚的样品,燃烧速度小于70毫米每分钟;或者在100毫米的标志前熄灭。

V-2:对样品进行两次10秒的燃烧测试后,火焰在60秒内熄灭。可以有燃烧物掉下。

V-1:对样品进行两次10秒的燃烧测试后,火焰在60秒内熄灭。不能有燃烧物掉下。

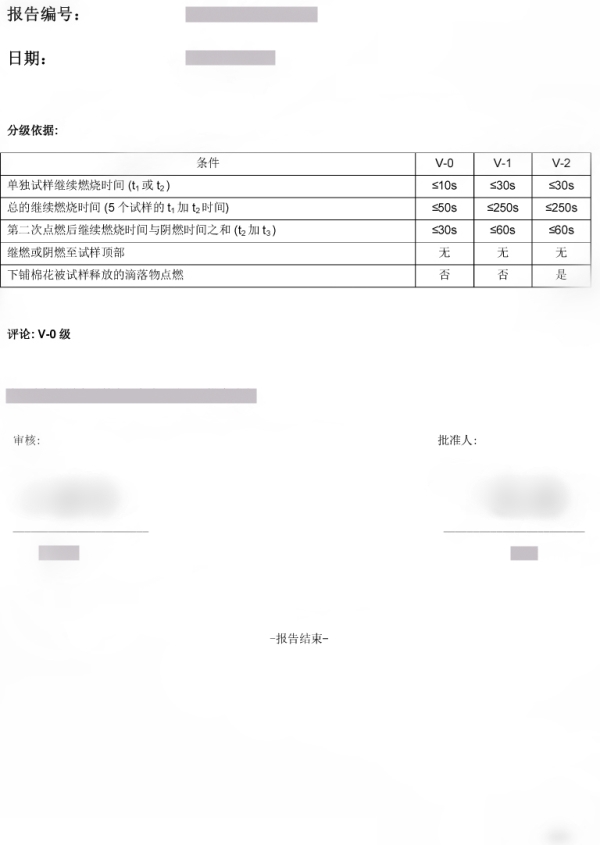

V-0:对样品进行两次10秒的燃烧测试后,火焰在30秒内熄灭。不能有燃烧物掉下。

每种被测材料根据颜色或厚度都可以得到许多值。当选定某个产品的材料时,其UL等级应满足塑料零件壁部分的厚度要求。UL等级应与厚度值一起报告,因此只报告UL等级而没有厚度是不对的。

Sample for reference 参考图片:

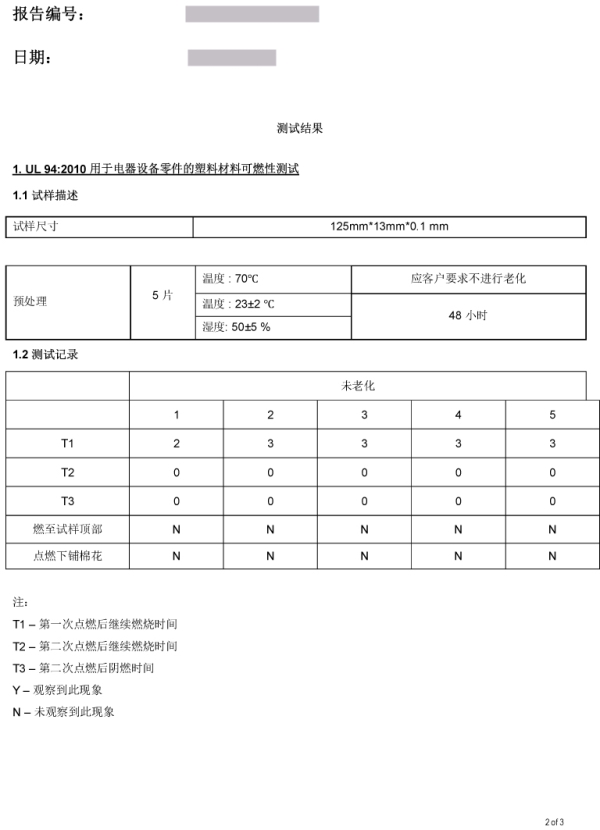

Sample Report 报告样本: