Steel – Round plain head nails – Specification

0 Foreword

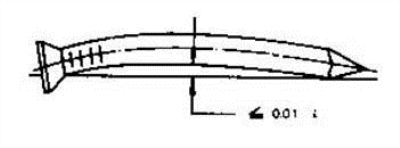

4.3 Eccentricity

The eccentricity, e, of the centre of the head to the axis of the shank as shown in figure 2 shall not be more than 12 % of the diameter of shank for nails equal to or greater than 2.00 mm in diameter, and shall not be more than 14 % for nails thinner than 2.00 mm diameter.

Figure 2 – Eccentricity of head

5 Scale of sampling and criteria for conformity

5.1 Lot

In any consignment all the packages of nails of the same type and size manufactured under essentially similar conditions shall be grouped together to constitute a lot.

5.2 Selection of nails

One sample package shall be selected from five packages or part thereof up to a maximum of 10 samples. From each sample package, 125 g of nails or 50 nails, whichever is greater, shall be taken and form the bulk sample. From the bulk, 125 g of nails or 50 nails in the latter case shall be taken for the test.

5.3 Dimensional and visual characteristics

All samples shall be checked for the following requirements:

a) nominal length L

b) nominal shank diameter d

c) nominal head diameter D

d) eccentricity of head e

e) sharpness s

f) bend of shank

g) freedom form burrs, cracks, flaws and other manufacturing defects.

5.4 Criteria for conformity

If less than five per cent of the test sample is found defective, the lot shall be accepted. If the reject exceeds five per cent but not greater than 10 %, two further equivalent samples shall be tested. The lot shall be accepted if the results of the two combined tests give less than five per cent of defective nails.

6 Packing

6.1 Nails of different sizes and types shall be packed in different containers.

6.2 Nails shall be supplied in gunny bags, and the net mass of each bag shall be 50 kg.

6.3 The nominal net mass of each bag shall have a tolerance of ±1 %.

7 Marking

All packages of nails shall be legibly marked with the following information:

a) manufacturer"s name and trade mark, if any

b) type of nails

c) shank diameter and length of nails

d) net mass of the package

e) approximate number of pins per kilogram

f) country of origin.

8 Designation

In making orders and in commercial and technical documents, round plain head steel wire nails (SWN) shall be designated as follows:

SWN / shank diameter and length / TZS 19:1979

Example: SWN / 4 x 90 / TZS 19:1979 shall mean steel wire nails of shank diameter

4 mm and length 90 mm as specified in this Tanzania Standard.

Table 1 – Dimensions and tolerances of steel round plain head nails (shank diameter 1.25 to 1.60 mm)

|

Shank diameter

d

|

Length

L

|

||

|

Nominal

|

Tolerance

|

Nominal

|

Tolerance

|

|

1.25

1.60

|

± 0.04

± 0.04

|

10

20

|

± 1.0

± 1.0

|

|

Shank diameter

d

|

Length

L

|

||

|

Nominal

|

Tolerance

|

Nominal

|

Tolerance

|

|

1.80

2.00

2.24

2.50

|

± 0.04

± 0.04

± 0.04

± 0.04

|

25

30

40

50

|

± 1.2

± 1.2

± 1.5

± 2.1

|

Table 3 – Dimensions and tolerances of steel round plain head nails) shank diameter 2.80 to 3.55 mm)

|

Shank diameter

d

|

Length

L

|

||

|

Nominal

|

Tolerance

|

Nominal

|

Tolerance

|

|

2.80

3.15

3.55

|

± 0.04

± 0.04

± 0.05

|

60

60

70

|

± 2.1

± 2.1

± 2.6

|

Table 4 – Dimensions and tolerances of steel round plain head nails (shank diameter 4.00 mm and above